Jintaijin's Revolutionary Patented Metal Frame Dry Grinding Machine: A Game-Changer in Polishing and Grinding

May 06, 2023

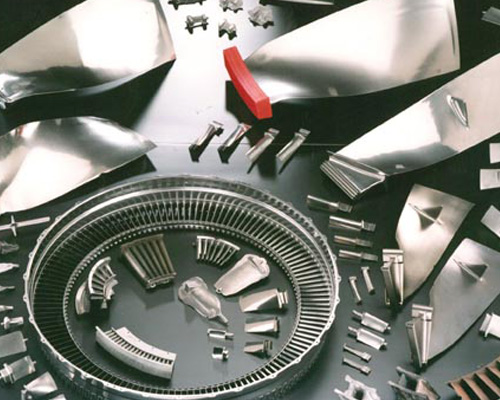

Introducing Jintaijin's Patented Metal Frame Dry Grinding Machine: High-Quality Polishing with Advanced Technology At Jintaijin, we are proud to introduce our state-of-the-art, patented Metal Frame Dry Grinding Machine (Model: OBD-BG01), designed to deliver superior polishing and grinding results across various industries. Our innovative machine incorporates advanced features and technical specifications that make it an essential addition to your production process. Machine Specifications: Model: OBD-BG01 Capacity: 40*4 Carrying capacity: 80 Dimensions (LWH): 168018002200 mm Motor: 3.7 KW Net Weight: 1600 KG Bamboo thickness: 25 mm Speed: 0-100 Key Features: Capacity: The machine can hold up to 8 hangers, allowing it to accommodate 480 metal eyeglass frames at once. Our verified stainless steel hangers prevent frame deformation while minimizing polishing blind spots. Efficiency: Each hanger rotates independently while following the rotation of the barrel, significantly enhancing the polishing efficiency. Intelligent PLC Control System: Our machine features a smart PLC control system for hanger positioning, which optimizes hanger numbering and positioning for increased efficiency and reduced costs. Bamboo Fiber Barrel: Compared to traditional wooden barrels, our bamboo fiber barrel has a higher density, resulting in reduced polishing oil consumption. Usage Instructions: Coarse grinding: Use coarse walnut granules and add coarse grinding polishing oil. Fine grinding: Use fine walnut granules and add fine grinding polishing oil. Electroplating: Some products may require this optional third step. *Note that the grinding media, polishing oil additives, and grinding time may vary depending on the specific product requirements. Application Fields: Our Metal Frame Dry Grinding Machine is suitable for various industries, including medical supplies, hardware accessories, metal tools, electronic products, and metal eyeglass frames. It is designed to provide precise grinding and polishing for metal eyeglass frames, accommodating up to 480 frames at a time. The hangers are compatible with frame and water grinding polishing machines, and each hanger can rotate independently. The barrel is made of bamboo, which has a higher density than traditional wooden barrels, reducing polishing oil consumption. Our machine is perfect for polishing and grinding applications in a wide array of industries, such as bathroom products, medical accessories, electronic accessories, automotive parts, castings, umbrella accessories, machined parts, zinc alloy die-castings, chains, bicycle accessories, motorcycle accessories, valve casings, saddlery, jewelry, stampings, carbon fiber, pins, eyeglass components, safety helmets, bone screws, prosthetic bone pins, bone plates, pliers, gas valves, buckles, clamps, bearings, angle valve casings, baffles, aluminum alloy parts, spring clamps, metal accessories, belt buckles, hardware workpieces, gears, door handles, ball joint boxes, springs...

View More