Item NO.:

OBD-HBPG-01Order(MOQ):

1Payment:

T/T, L/C, Western Union,Money GrainMarket Price:

$3500Price:

$3500/SetPrice Range:

3 - 10/$3500Product Origin:

ChinaColor:

YellowShipping Port:

XiamenLead Time:

30 daysWeight:

500Product Detail

Industrial Vibratory Polishing Machine Grinding Polisher Tumbler Equipment Bowl

Successful mass finishing applications are usually the result of a combination of creative process technology and innovative equipment engineering. This approach is reflected in the varied line of Jintaijin rotary vibrators with their enhanced performance characteristics. They combine Jintaijin’ s high equipment quality and reliability standards with a functional design. In addition, they are easy to operate and provide a high degree of productivity.

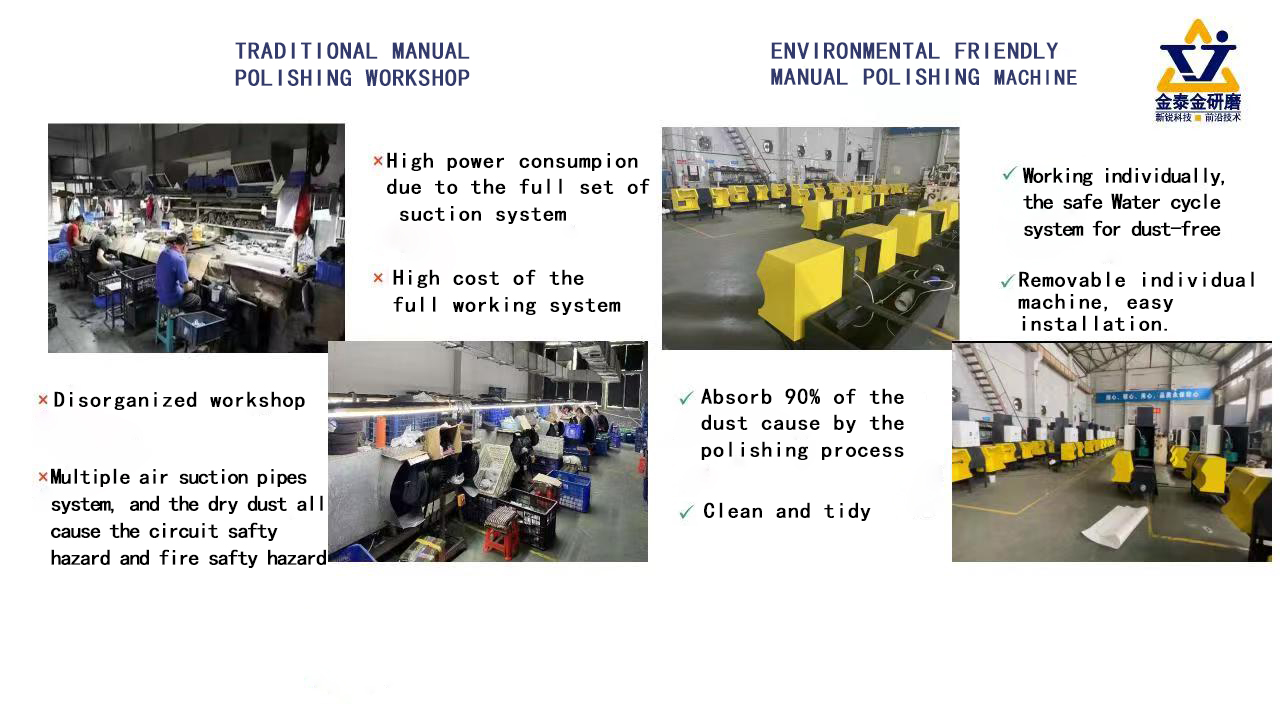

Disorganized workshop

Multiple air suction pipes system, and the dry dust all cause the circuit safty hazard and fire safty hazard

High power consumpion due to the full set of suction system

High cost of the full working system

Environmental Friendly Manual Polishing Machine :

Clean and tidy

Working individually,the safe Water cycle system for dust-free

Absorb 90% of the dust cause by the polishing process

Removable individual machine, easy installation.

FAQ

Q: Which sulotions/machine/abrasive suitable for us ?

A:Wewill suggest the sulotions/machine/abrasive according to the testing report after free testing of your aplicationsifyou cansent us your products.

Professional advice:Our finishing specialists stand ready to provide answers to any question relating to specific surface finishing problems.Our decades of experience ensures that we will be able to provide you with the riaht answers

Email : info@surface-polish.com