Item NO.:

OBD-70AOrder(MOQ):

1Product Origin:

ChinaShipping Port:

XiamenLead Time:

30 daysWeight:

60000Product Detail

A Hot Air Drying System -- Centrifugal Spin Dryers

Centrifugal Spin Dryers are also called Hot Air Centrifugal Dryers and Centrifugal Spin Dryers. Centrifugal dryer used to remove moisture from a variety of materials. It works by using a combination of heat and centrifugal force to spin the material at high speeds, allowing moisture to be removed from the surface and collected in a separate compartment. Mass Polishing provides two types: economy type & heavy basic type both have two sizes: 35kgs, and 70kgs. You can use it as an independent running unit, and also can be run with our other units to achieve a mass finishing line.

“I don’t know how to choose the Centrifugal Spin Dryer and Drying Media.”

Contact us here for more information and a free quote!

Features

> Economic & heavy-duty centrifugal hot air

> Cost-saving drying & deoiling process

> Brake pedal stops the basket quickly

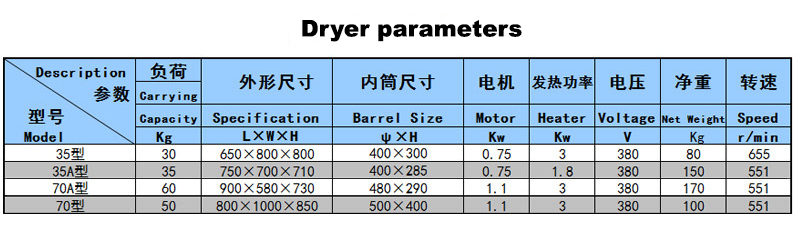

Technical Data

Options

> Control Panels with Timer

> Variable Frequency Driver

> Pneumatic Cover Open & Close

> Customized Size Buckets

Related Tags :

Email : info@surface-polish.com