Item NO.:

OBD-YG350Payment:

T/T, L/C, Western Union,Money GrainProduct Origin:

ChinaShipping Port:

XiamenLead Time:

30 daysWeight:

250000Product Detail

A Safe Barrel Finishing Technique -- Wood Barrel Dry Polishing Machines

Rotary Barrel Dry Polishing Machines come in a range of sizes and configurations, making them suitable for use in a variety of applications. Some models are designed for use with small parts, while others are capable of handling larger components. These machines can be outfitted with a variety of abrasive media, such as polishing compounds and buffing pads, to achieve the desired level of finish on the material being polished. They are often used in conjunction with other finishing equipment, such as deburring machines and vibratory tumblers, to achieve the desired level of surface quality and precision. Wood Barrel Dry Polishing Machine with Safety Cover, and other optional settings, make processes safe.

“I don’t know how to choose the Wood Barrel Dry Polishing Machine and Vibratory Tumbling Media.”

Contact us here for more information and a free quote!

Applications

> Grinding and polishing of metal parts

> Hardware, plastic products, and acetate glasses frames

> Automobile and motorcycle parts

> Medical products

Features

> International standards, stable and durable steel structure

> Wear and tear-resistant, environmentally friendly, and heat-dissipating high-density bamboo barrel

> Easy control operation

> Stable transmission and fine performance with standardized machine parts

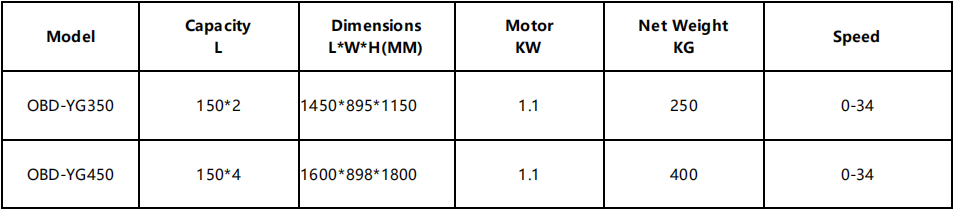

Technical Data

Related Tags :

Email : info@surface-polish.com