Ceramic media is a type of polish media suitalbe for fine polishing,mainly for surface finishing of metal applications.The surface of the media is fine and hard, we have produce different shapes and hardness, including polishing balls, cylinder and triangle.

Item NO.:

OBD-GPCOrder(MOQ):

100Payment:

T/T, L/C, Western Union,Money GrainMarket Price:

$3.8Price:

$3.8/kgPrice Range:

500 - 1000/$3.8Product Origin:

ChinaColor:

Brown/whiteShipping Port:

XiamenLead Time:

30 daysWeight:

1Product Detail

Polishing Ceramic Grinding Material Polish Stone Rock Surface Finishing Abrasive

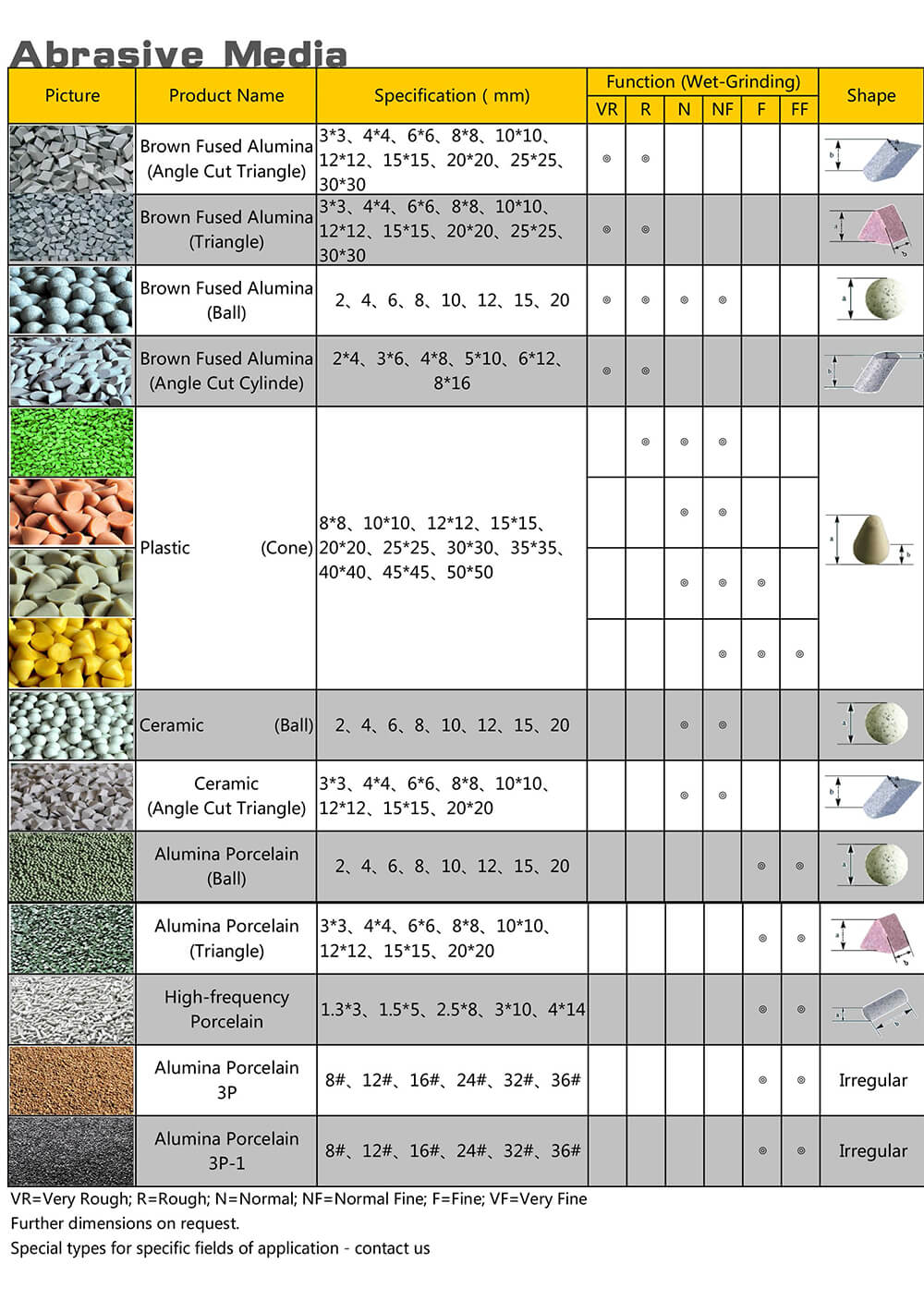

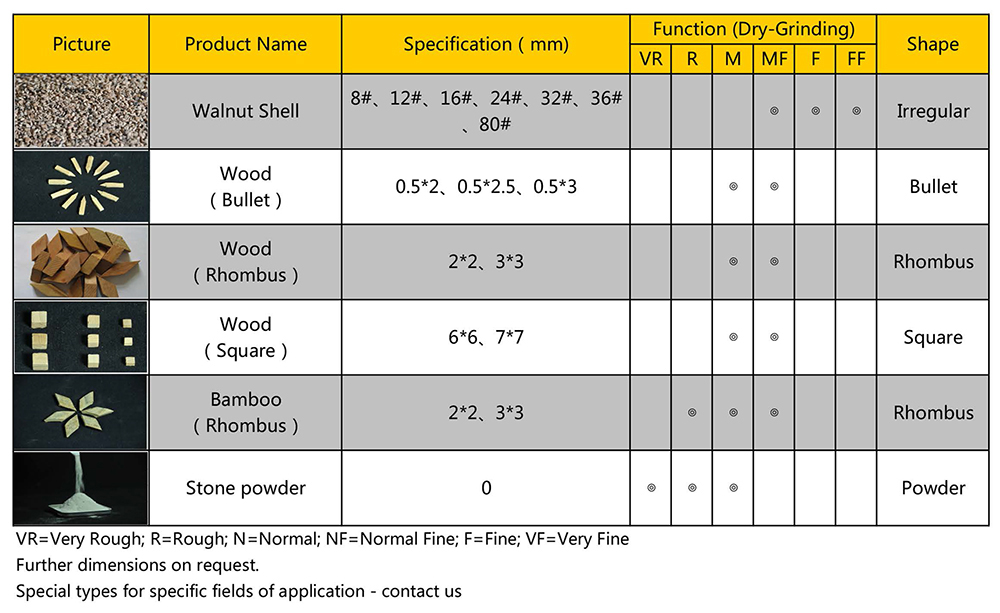

We manufacture various sizes and compositions of ceramic media in our production facilities. This ensures that the right media is available for each application. Special customer specific solutions can also be produced. Our test labs and our media production facilities work together to develop media that meets special requirements. All consumables – ceramic and plastic media, compounds, and auxiliary media are manufactured to the highest quality standards.

Our product range of media and compounds is by far one of the most comprehansive in the world due to our 30 years of constant product development and improvement.There are more than 2000 different kinds of polishing media, grinding compound and abrasive in our product range. We keep providing our worldwide customers surface finishing solutions and possibilities of different kinds of applications.

Fine polishing mainly for metal applications including: Hardware like bathroom products, medical parts, electronic parts, auto parts, Casting,casting of umbrella accessories, machined parts, zinc alloy die castings, Chain polishing, bicycle accessories, motorcycle accessories, flushing valve casing, jewellery, stamping, pin polishing, Metal eyewear accessories, hard hat ,bone screw , artificial bone, Bone plate, pliers, gas valve, buckle, fixture, Bearing washer , angle valve casing , baffle, aluminum alloy , Spring clip, metal fitting , belt buckle, metal workpiece , Gear, door handle , ball box, spring, rivet , Bulb socket, ceramic parts, shoe buckle, machined aluminum, Zipper , tent clip, hook , shovel, blade, Daily hardware, hardware tool, agricultural tools, woodworking tools, Pipe rack , white steel bar, tungsten machining, machining hardware, Separator, medical tweezers , stainless steel tweezers plastic tweezers polishing, 3D printing polishing and so on...

FAQ

Q: Which sulotions/machine/abrasive suitable for us ?

A:Wewill suggest the sulotions/machine/abrasive according to the testing report after free testing of your aplicationsifyou cansent us your products.

Professional advice:Our finishing specialists stand ready to provide answers to any question relating to specific surface finishing problems.Our decades of experience ensures that we will be able to provide you with the riaht answers

We have CE certificates for the products and IS09001 certificate for our factory.we have strict OC checking every details of the machine and full testing running before ship the machine.And we provide different wanrranties to the products.

Email : info@surface-polish.com