Vibration Wheel Polishing Machine""Deburring Barrel Polishing Machine"Deburring Machine""Vibration Polishing Machine For Metal""Vibration Polishing Machine Wheels""Wheel Polishing Machine Vibrator""Automatic Deburing Polishing Machine"

"Vibration Finishing Polishing Machine""Polishing Machine Polishing Machine""Polishing Deburring Machine""Surface Metal Polishing

Item NO.:

OBD-ZL300Order(MOQ):

1Payment:

T/T, L/C, Western Union,Money GrainMarket Price:

$6500Price:

$6500/SetPrice Range:

3 - 10/$5800Product Origin:

ChinaColor:

YellowShipping Port:

XiamenLead Time:

30 daysWeight:

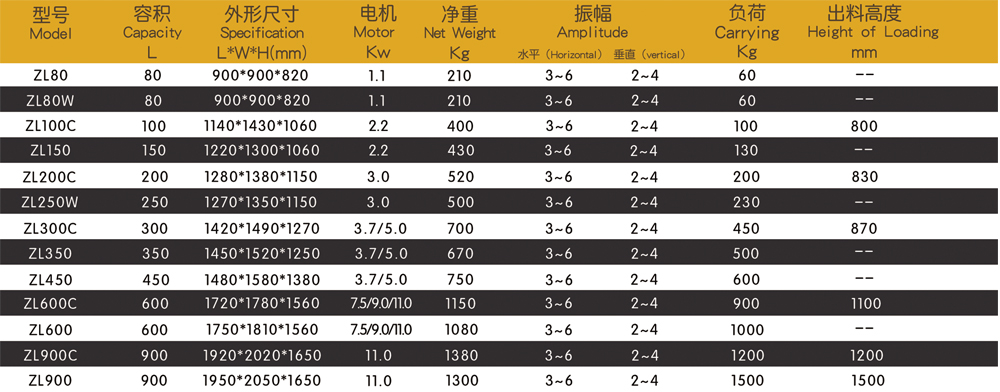

700Product Detail

Industrial Vibratory Polishing Machine Grinding Polisher Tumbler Equipment Bowl

Successful mass finishing applications are usually the result of a combination of creative process technology and innovative equipment engineering. This approach is reflected in the varied line of Jintaijin rotary vibrators with their enhanced performance characteristics. They combine Jintaijin’ s high equipment quality and reliability standards with a functional design. In addition, they are easy to operate and provide a high degree of productivity.

Functionable: Functionable include:de-burring,grinding,radiusing,general parts cleaning,casting,formed,forged and saw-cut pa ts as well as machined components.

For the surface treatment of acetate, plastic, metal and other products, improve the flatness of the surface of the product, brightness, for the subsequent processing Efficiency and cost savings.

Application areas: polishing and polishing of bathroom products, polishing of medical parts, polishing of electronic parts, polishing of auto parts, Casting and polishing, casting of umbrella accessories, polishing of machined parts, polishing of zinc alloy die castings, Chain polishing, bicycle accessories polishing, motorcycle accessories polishing, flushing valve casing polishing, Horse polishing, jewellery polishing, stamping polishing, carbon fiber polishing, pin polishing, Metal eyewear accessories polishing, hard hat polishing, bone screw polishing, artificial bone nail polishing,Bone plate polishing, pliers polishing, gas valve polishing, buckle polishing, fixture polishing, Bearing washer polishing, angle valve casing polishing, baffle polishing, aluminum alloy polishing, Spring clip polishing, metal fitting polishing, belt buckle polishing, metal workpiece polishing, Gear polishing, door handle polishing, ball box polishing, spring polishing, rivet polishing, Bulb socket polishing, ceramic parts polishing, shoe buckle polishing, machined aluminum polishing, Zipper polishing, tent clip polishing, hook polishing, shovel polishing, blade polishing, Daily hardware polishing and polishing, hardware tool polishing, polishing of agricultural tools, polishing of woodworking tools, Pipe rack polishing, white steel bar polishing, tungsten machining polishing, machining hardware polishing, Separator polishing, medical tweezers polishing, stainless steel tweezers polishing, plastic tweezers polishing, 3D printing polishing and so on...

FAQ

Q: Which sulotions/machine/abrasive suitable for us ?

A:Wewill suggest the sulotions/machine/abrasive according to the testing report after free testing of your aplicationsifyou cansent us your products.

Professional advice:Our finishing specialists stand ready to provide answers to any question relating to specific surface finishing problems.Our decades of experience ensures that we will be able to provide you with the riaht answers

Q: How about the delietverv ?

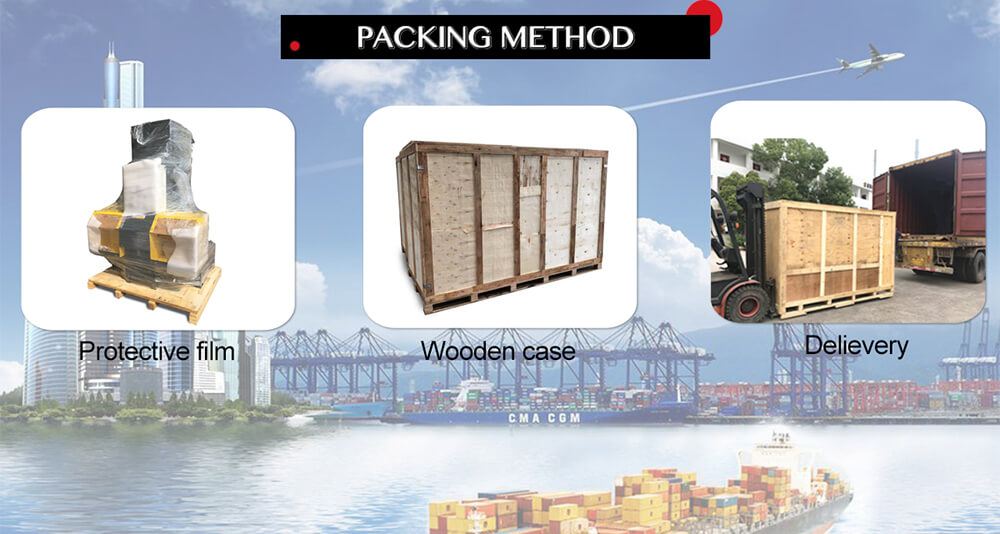

Thepaymentterms is 30% deposit and 70% balance before shipment. And 15~30 days for production.1~3 days for stocks.The packaae always be wooden case.and we could arrange shipment for you by sea by air or by express(Door to Door

Vibration Wheel Polishing Machine""Deburring Barrel Polishing Machine"Deburring Machine""Vibration Polishing Machine For Metal""Vibration Polishing Machine Wheels""Wheel Polishing Machine Vibrator""Automatic Deburing Polishing Machine"

"Vibration Finishing Polishing Machine""Polishing Machine Polishing Machine""Polishing Deburring Machine""Surface Metal Polishing

Email : info@surface-polish.com