The Profound Impact of Product Polishing: Elevating Quality, Durability, and Efficiency | Jintaijin Polishing

September 23, 2023

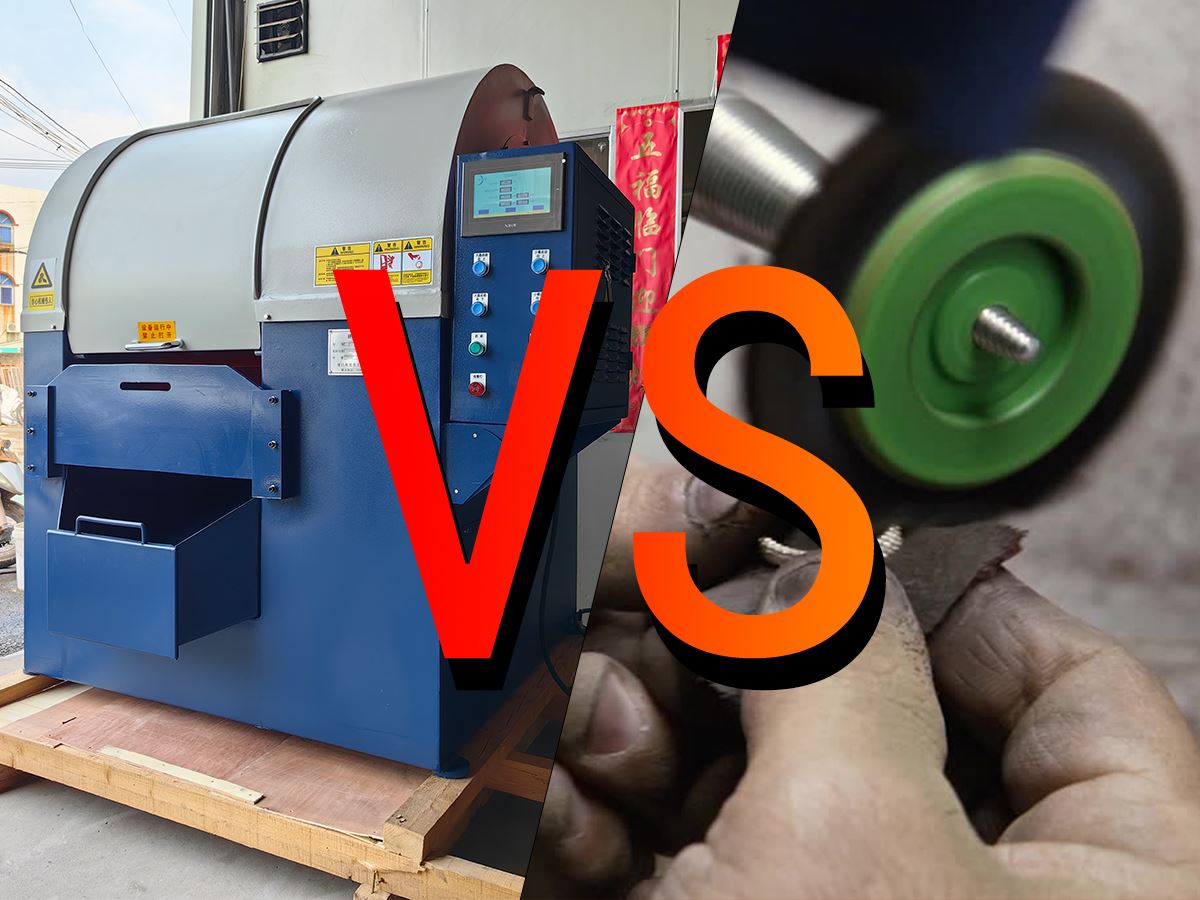

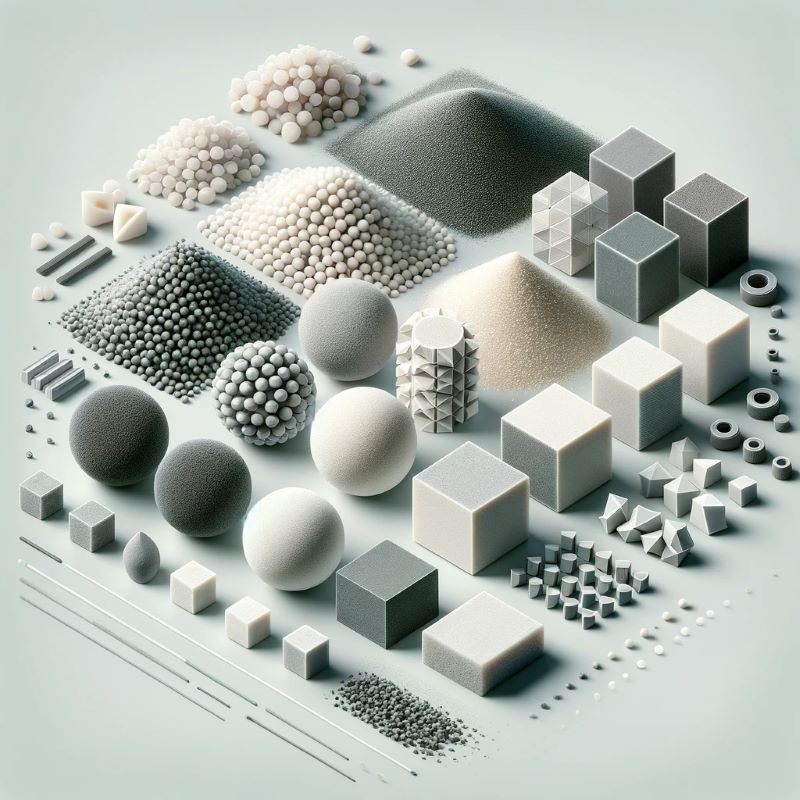

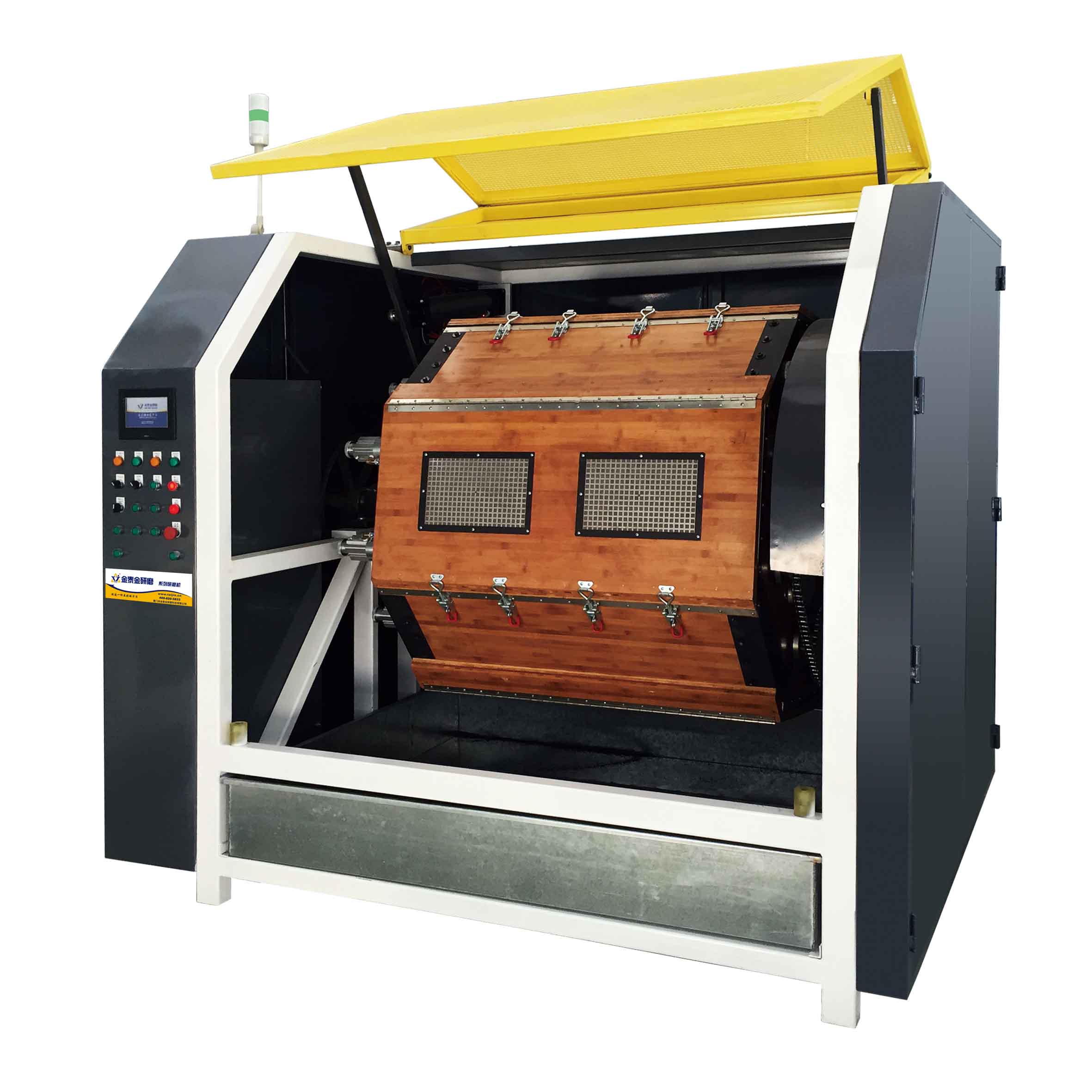

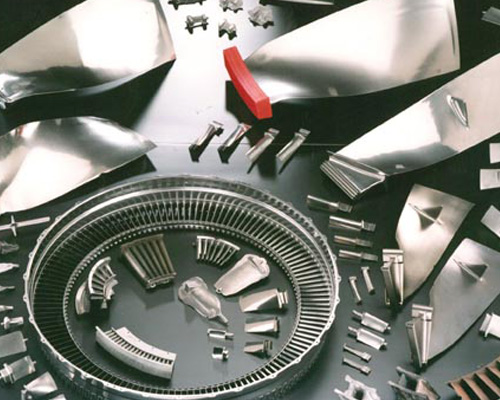

The Profound Impact of Product Polishing: Elevating Quality, Durability, and Efficiency | Jintaijin Polishing Introduction: Product polishing is a transformative and highly specialized manufacturing process that significantly influences multiple industries, including aerospace for aircraft components, precision engineering for stainless steel products, healthcare for medical equipment, automotive for aluminum alloy products, and more. This comprehensive article will delve deeply into the nuanced and multifaceted benefits of product polishing, emphasizing the intricacies of the process. Additionally, we will outline the key steps involved in the product polishing process, providing valuable insights into this crucial aspect of modern manufacturing. Benefit One: Impeccable Surface Finish In industries where precision, aesthetics, and functionality converge, the quality of a product's surface finish is of paramount importance. Polishing, as a meticulous art, accomplishes more than mere aesthetics—it ensures product functionality and durability by perfecting the surface. During the process, skilled technicians at Jintaijin Polishing employ a range of abrasive materials and techniques to eliminate imperfections such as scratches, burrs, pits, or oxidation. The result is a surface that reflects light flawlessly, providing a mirror-like, smooth finish that not only appeals to the eye but also enhances the product's performance and longevity. Benefit Two: Enhanced Durability and Corrosion Resistance The significance of polishing extends far beyond cosmetic enhancements. Polishing profoundly augments a product's resistance to corrosion and wear, a vital consideration in industries where product longevity is critical. By meticulously removing surface defects, contaminants, and micro-imperfections, the polished surface becomes highly resistant to the corrosive effects of environmental factors, such as moisture, chemicals, or extreme temperatures. This extends the product's lifespan, reduces maintenance requirements, and ultimately lowers the cost of ownership. Aerospace components, medical devices, and marine equipment all benefit significantly from this enhanced durability. Benefit Three: Streamlined Production Processes The process of product polishing is a well-orchestrated sequence of meticulously executed steps: Surface Preparation: Prior to any polishing activities, the product's surface undergoes rigorous preparation. This involves thorough cleaning and degreasing to ensure that the surface is free from contaminants that might hinder the polishing process. Proper preparation sets the stage for optimal polishing results. Rough Polishing: The initial phase of polishing involves the use of coarse abrasives to remove surface imperfections and irregularities. This phase is critical in addressing issues like deep scratches, dents, or substantial surface roughness. Fine Polishing: Following rough polishing, finer abrasives are employed to further refine the...

View More